District heating reimagined: Install more metres per day and accelerate project success with aquatherm energy twin

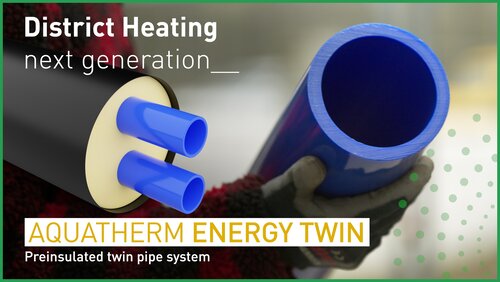

With the new aquatherm energy twin, aquatherm presents a pre-insulated piping solution that combines easy processing, high energy efficiency, and sustainability in one system. As a new variant, it expands the established aquatherm energy product family and adds an important advantage: combined flow and return pipes in a single jacket – ideal for confined spaces and fast, space-saving installation in district heating projects.

The integrated dual system not only reduces excavation volume but also significantly shortens installation time. Thanks to the lightweight plastic design, handling on-site is much easier compared to heavy steel pipes.

A socket welding device developed in cooperation with Ritmo SPA enables both medium pips to be welded simultaneously in a single step – cutting connection time by up to 50% compared to conventional methods. The weld seams are produced synchronously and automatically monitored, ensuring maximum process reliability with minimal effort.

This solution is unique worldwide and sets new standards in plastic welding technology. Read more.