What can the AQUATHERM ENERGY pre-insulated pipework system do?

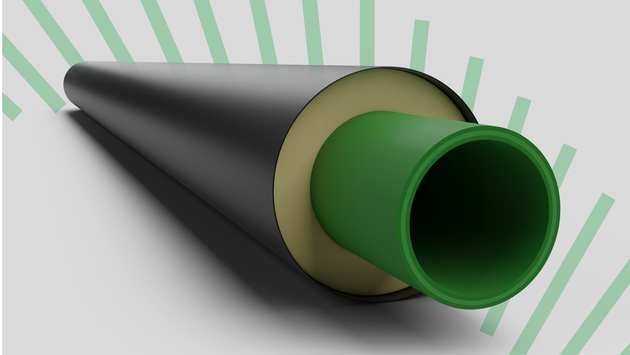

The aquatherm energy pipework system consists of pre-insulated polypropylene pipes, fittings and joints. All service pipes and fittings used for aquatherm energy are made of the material Fusiolen PP-R/PP-RCT. These are insulated with PUR foam and enclosed in an HDPE casing pipe.

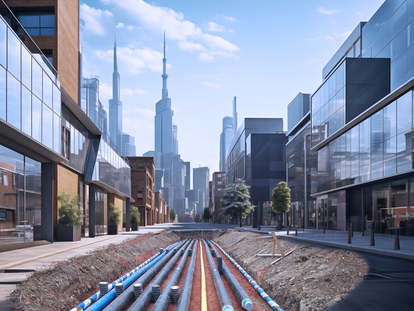

The pre-insulated aquatherm energy pipe is particularly suitable for energy-efficient heat and cold transport. The system is the solution for many different applications for distributing heat and cold fluids, including in heating and cooling networks, water distribution, geothermal energy, swimming pool technology, open-space cooling, refrigeration systems, open-space heating and air conditioning systems.

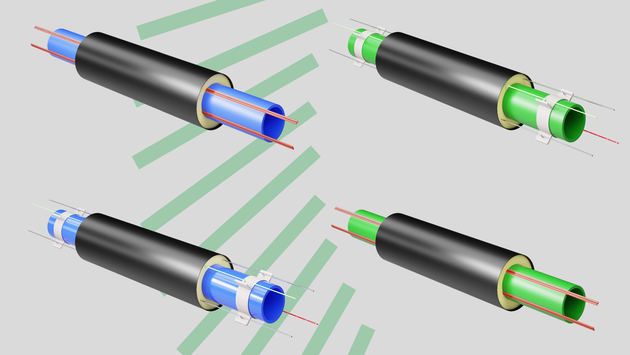

aquatherm offers pre-insulated pipework systems in various pressure ratings in sizes from 32 - 355 mm. There are also pre-insulated fittings for bends and T-pieces as well as shrink sleeve sets WTD with moulded part for 32-125 mm service pipes.

aquatherm energy pipework systems are insulated with PUR foam that fulfils the functional requirements of DIN EN 253. The foam is homogeneous with an average cell size of no more than 0.5 mm.

The diameter of the PP pipe determines its location and intended use. The pipe diameter of the individual pipes and fittings must be compatible so that you can lay a pipe from the connection to the outlet.

aquatherm energy consists of several layers of material to provide unique strength and insulation properties:

The SDR (Standard Dimension Ratio) is an indicator of pressure resistance. In order to guarantee a certain pressure resistance, a certain maximum SDR number is required, depending on the type of material. The following applies: the greater the wall thickness, the lower the SDR number and the more pressure-resistant the plastic pipe. The unit indicates the ratio between the outer diameter and wall thickness of a pipe. aquatherm energy is available in the following SDR sizes:

The polypropylene carrier pipe from aquatherm energy offers a number of advantages over conventional steel pipes:

- Low weight

- No corrosion

- High stability

- High impact resistance

- Less roughness inside the pipe

- Resistant to most chemicals

- Very good welding properties

- Self-insulating