aquatherm blue used as a geothermal probe in a new school centre

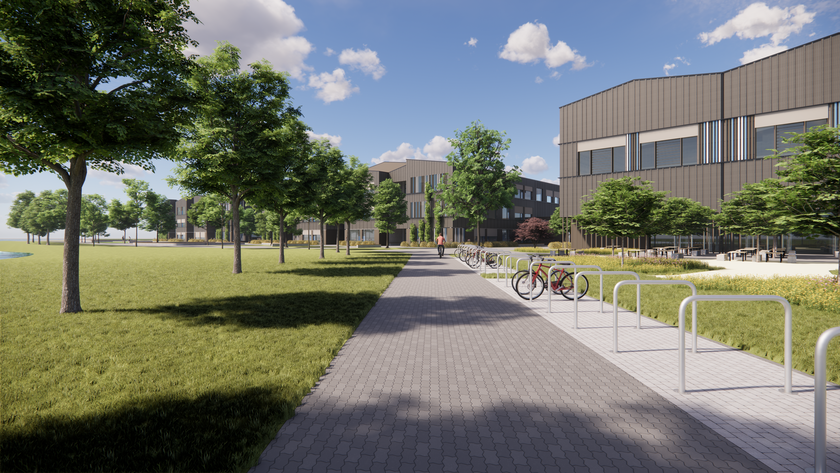

How can a school building be designed today to not only meet the requirements of modern learning but also sets standards in energy efficiency – and on a site that is almost completely surrounded by water? This question was at the heart of the planning for the new inclusive school centre Am Ellernholzteich in Greifswald, Germany.

This is not just another school complex; it is a forward-looking educational campus that breaks new ground with its technical equipment. The total cost of this major project is around 76 million euros, and the school centre will accommodate approximately 700 pupils. The first pupils are expected to start learning at the new educational campus in the 2028/2029 school year.

The modern facility combines a primary school, regional school, after-school care centre, canteen, and a three-part sports hall to create an inclusive learning environment that enables flexible educational concepts. The natural design of the schoolyard, with accessible paths and play facilities for wheelchair users, reflects the inclusive approach.

Planned in accordance with DGNB standards

The entire project was planned in accordance with the sustainable building guidelines of the DGNB (German Sustainable Building Council). A photovoltaic system covers part of the electricity requirements, the roof areas are greened to retain rainwater for use in planting, and the building services also follow sustainability principles.

The special location of the site, which is almost completely surrounded by water – including the Ellernholzteich pond – placed high demands on the planning and construction logistics. The building was founded on 333 bored piles that reach down to the load-bearing soil, securing the foundations of the complex. The piles also provide a remarkable solution for additional heating and cooling: around two-thirds are geothermally activated to supply renewable energy for pre-cooling the mechanical ventilation and for supporting heating in the building.

Thermally activated bored piles

The bored piles are activated using aquatherm blue from aquatherm. Around 10,000 metres of the piping system were installed as geothermal probes. Approximately 3,200 welds were required, which were carried out during prefabrication at aquatherm's headquarters in Attendorn. To ensure the safety of groundwater during installation and operation, the probes were individually pressure-tested at the factory and delivered to the construction site under pressure using special monitoring systems. This guaranteed that any damage occurring during transport or until the probes were connected to the Tichelmann system would be reliably detected.

The probes were woven into 210 metal reinforcement cages and then set in concrete in pre-drilled holes on the construction site. The boreholes have diameters of 90 to 120 centimetres and reach depths of up to 12 metres.

The oxygen-tight version of the piping system, aquatherm blue ot, was used to prevent corrosion in the plant engineering. Oxygen diffusing through the pipe wall can cause corrosion on metallic elements, leading to damage and a shortened service life. The oxygen barrier layer of aquatherm blue ot prevents this diffusion, ensuring system safety.

The piping system is filled with brine, a mixture of water and antifreeze. This heat transfer fluid extracts heat from the ground (for heating) or transfers heat to it (for cooling).

Using two parallel brine-water heat pumps, the temperature level is increased to a level suitable for heating the building. A total of approx. 150 kW of heat is to be extracted from the ground via the activated piles. The heating system is a bivalent: in addition to the basic supply via the brine-water heat pumps, the buildings are connected to a district heating station to cover the remaining heating requirements.

Advantages of aquatherm blue

Thanks to its product properties, aquatherm blue offers numerous advantages for the construction project:

- Corrosion-resistant material aquatherm blue is made of polypropylene (PP), with physical properties specifically tailored to the requirements of the heating and cooling sector.

- Durability: The material is resistant to corrosion and deposits, ensuring a long service life.

- Exceptional weldability: aquatherm pipes and fittings fuse together to form a homogeneous, material-locked unit – without any metallic elements. To achieve this, the pipe and fitting are briefly heated using special tools and then simply joined together.

Next steps with aquatherm

The next phases of the construction project have already been planned: in spring 2026, aquatherm will supply the Tichelmann manifolds for connecting the probes in the floor slab, followed by the installation of the heating and air-conditioning piping in 2027. aquatherm blue will also be used in the cooling water system, ensuring a reliable supply to the ventilation and air-conditioning systems.