aquatherm blue ensures perfect winter sports conditions

In Haarlem, the Netherlands, about 30 kilometres west of Amsterdam, the dream of many ice skating fans came true. The expansion and modernisation of the "IJsbaan Haarlem" middle areas created a spacious, multifunctional ice rink measuring 110 by 30 metres. The modernised hall can be flexibly subdivided, allowing ice hockey, figure skating, short track, and recreational skating to take place simultaneously.

Behind this impressive redesign is real engineering: the new cooling system was implemented using the aquatherm blue piping system and a perfectly coordinated system.

Planning and digital modelling

RIHO Climate Systems played a central role as planner and installer. From the outset, the project was planned entirely with BIM software Revit. RIHO project manager Bram van der Ree explains:

"aquatherm's extensive BIM database helped us enormously in modelling the entire plant. Every line and detail was thought through in advance, ensuring safety and oversight on the construction site."

The ice rink was fully planned digitally, from the concrete channels for the pipes to the connections to the prefabricated distributors. Thanks to this detailed preparation, on-site implementation was quick and error-free.

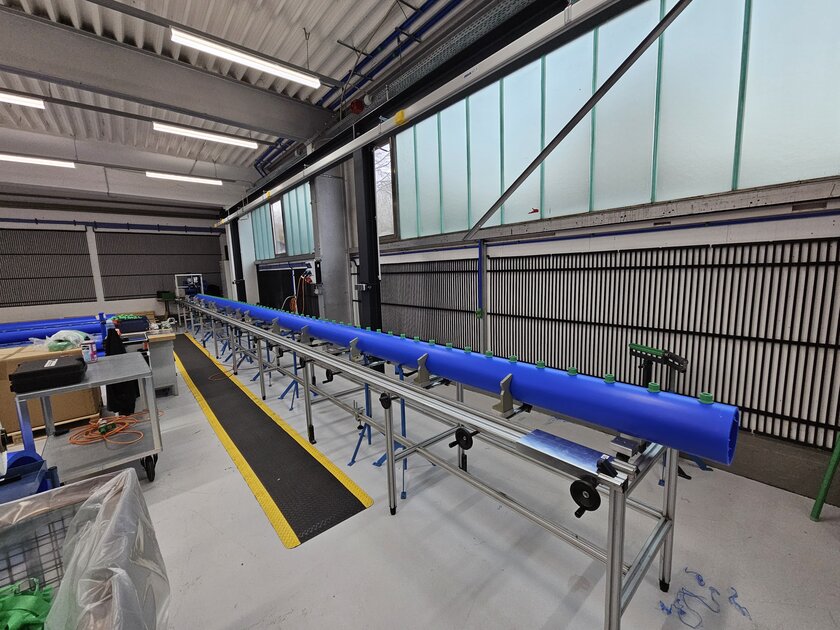

Pipeline installation: 45 kilometres of precision

A total of 45,000 metres of aquatherm blue were laid across 700 sections. The pipelines were carefully welded, secured, and tested using specialised tools. They were installed on steel plates, in two layers with insulation and foil in between to compensate for expansion and contraction. Depending on the pipe diameter, both socket and butt welds were used. This construction provides a durable foundation for the ice floor.

Prefabrication: saving time and ensuring quality

A key feature of the system was the main distributor, delivered prefabricated by aquatherm via its Dutch partner ERIKS. With diameters of up to 200 mm and a total weight of over two tonnes, the manifold was fully pre-assembled at aquatherm’s headquarters in Attendorn, ready for direct installation.

Pipe bends, connecting the supply and return lines, were also partly prefabricated by RIHO in its Vorden workshop. This close collaboration between aquatherm, ERIKS, and RIHO minimised on-site assembly time, which was crucial given the tight seasonal construction window.

Prefabricated, insulated mains

Another important component was the pre-insulated aquatherm energy pipelines, connecting the machine room with the main distributor. These 315 mm medium pipes, made of aquatherm blue, not only reduced installation time and costs but also provide optimal protection and durability for decades of reliable operation.

Cooling system upgrade

The ice rink’s cooling system was converted from a CO₂ injection system to an alkali-based ammonia/water solution. This medium operates at relatively low pressure, making it ideal for use with plastic pipes such as aquatherm blue.

Ready for the future

The renovation of the ice rink in Haarlem is a prime example of technical innovation, teamwork, and craftsmanship. The new facility offers significantly more usable space and was designed with sustainability in mind, including measures such as a new roof and integrated solar systems.

The ice floor is designed for intensive use and is suitable for both recreational athletes and professionals. Thanks to the advanced cooling system and high-quality components, the ice rink is ready for decades of use.