Energy transition with security

New at aquatherm: Leakage monitoring of heating and cooling networks

In some industries, regulations and standards govern the safe operation of pipelines. This also applies to district and local heating and cooling networks. Leakage monitoring helps to comply with these regulations and make heating and cooling networks even safer. aquatherm is now offering corresponding systems for its aquatherm energy product family, therefore setting new standards for the reliability of pipes made of polypropylene plastic.

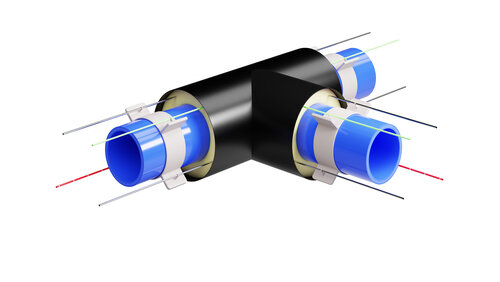

Two systems are offered, each of which locates leaks with pinpoint accuracy by passing on signals and automatically reports them to the central monitoring unit. The system from Brandes GmbH - a system supplier and service provider for over 50 years for early moisture detection and leak detection in pipes, among other things - is installed in the insulation of the piping system. In the system from the manufacturer Wideco, which has been on the market since 1982 and secures more than 40,000 km of transmission and distribution networks around the world with its products, the sensors are located directly on the pipe. Both systems enable early detection of leaks before they lead to property or environmental damage, business interruptions and high repair costs.

Pre-insulated piping solutions

With leakage monitoring, aquatherm rounds off its portfolio in the field of the aquatherm energy piping system. This consists of pre-insulated polypropylene pipes as well as fittings and joints. All medium pipes and fittings used for aquatherm energy are made of the material fusiolen PP-R/PP RCT. These are insulated with PUR foam and enclosed with an HDPE casing pipe. The system is the solution for many different heat and cold liquid distribution applications, including heating and cooling networks, water distribution, geothermal energy, swimming pool technology, open space cooling, refrigeration, open space heating and air conditioning. The advantages of the system are particularly evident as an oxygen-tight variant: Thanks to a special coating, no oxygen gets into the water, which could lead to corroded pumps or valves. Corrosion of the pipe itself - whether from the inside or outside - is excluded by the material polypropylene.